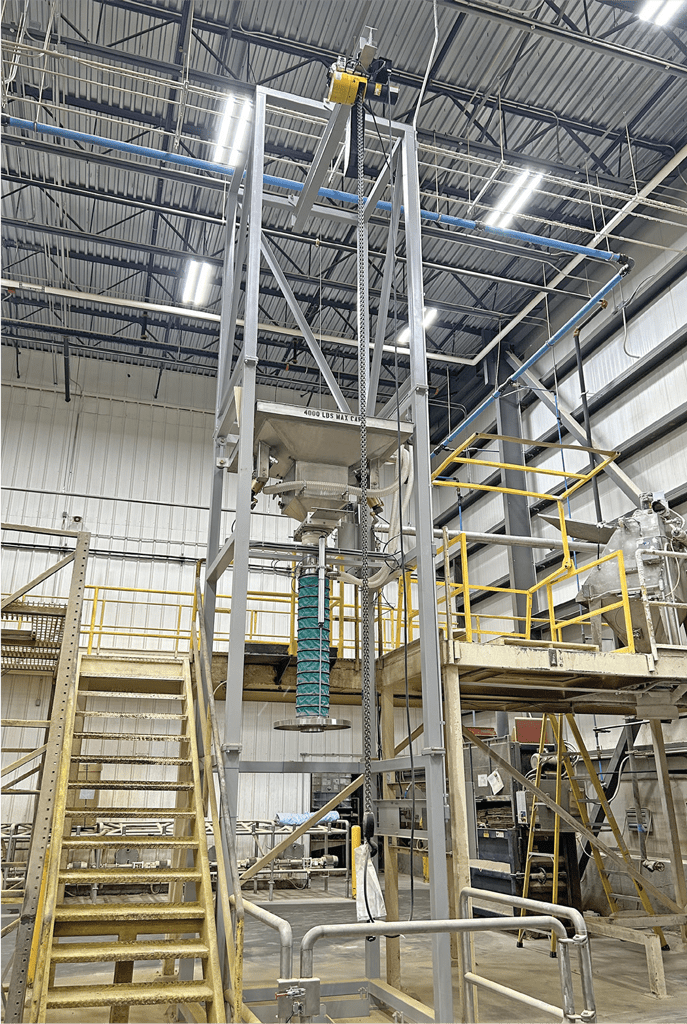

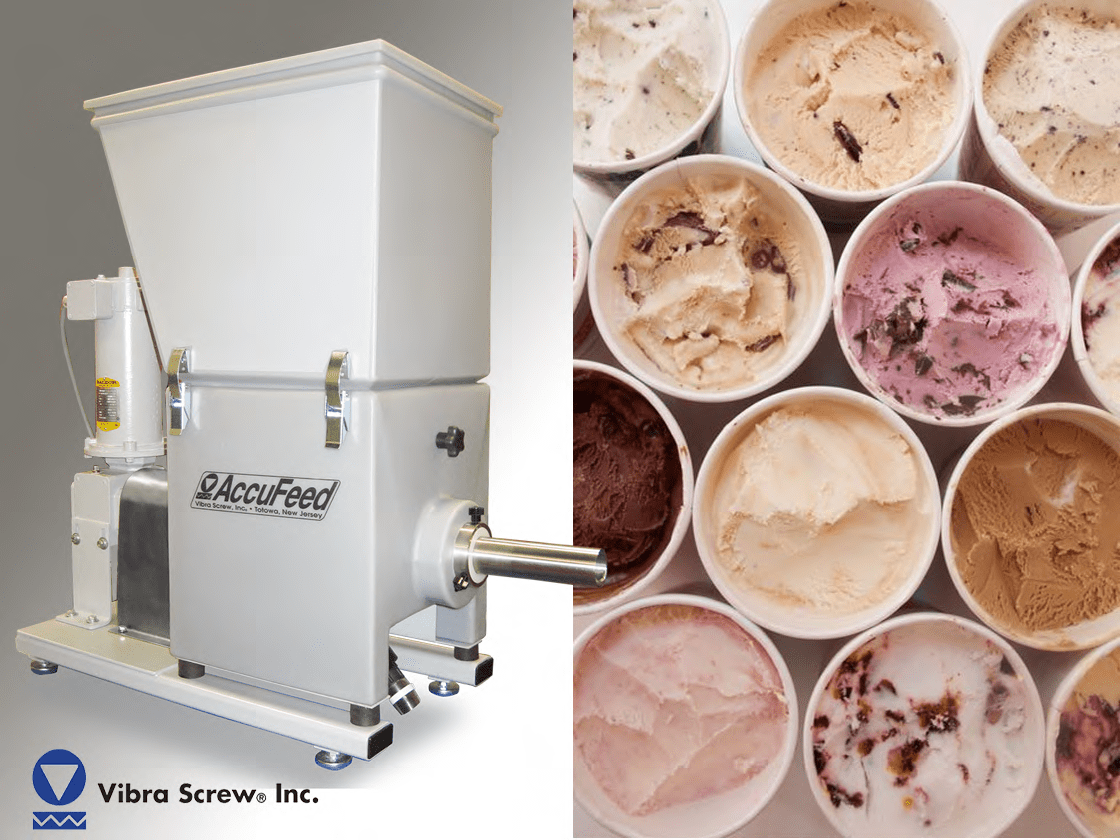

TOTOWA, NJ — Vibra Screw, Inc., a leader in solids processing and solids handling solutions, offers AccuFeed Loss-in-Weight Feeders that provide accuracies to ± 1/4% in gravimetric mode, where the weight signal is far more stable than in other systems.Designed to maximize accuracy through controlled vibration during the refill cycle, the Vibra Screw AccuFeed plastic-bodied Loss-in-Weight Feeder is available in screw diameters from 1” – 6” and capacities from 2.8 to over 600 cu.ft./hour. The units are constructed of food grade polyethylene which is inert and non-corrosive. The Feeder offers versatility in hopper selection, adapts easily to a wide variety of storage/discharge systems, and affords easy cleaning between material changes.AccuFeed is also available off-the-shelf at a price significantly lower than comparable steel loss-in-weight feeders, and is easily adapted to a broad range of applications by the simple addition of a secondary trough conditioning screw for non free-flowing materials. User-friendly, microprocessor-based controls feature a membrane keyboard and easy-to-read display that distinguishes actual weight from plant electronic noise. As with all Vibra Screw equipment, the AccuFeed Loss-in-Weight Feeders are unconditionally guaranteed to perform in the service for which they are sold. With a staff of experienced and talented engineers, technicians and crafts people, Vibra Screw manufactures high quality equipment to store, discharge, meter, convey, size and blend solid materials. The company’s comprehensive product range includes bulk bag unloaders and fillers, volumetric feeders, bin activators, vibrating feeder/conveyors, loss-in-weight feeders, storage pile activators, live bottom bins, live bins, continuous blenders, screeners, controls, and turnkey systems.

Ever wonder how they get those wonderful little pieces of goodies inside of ice cream. You know those chunks of toffee, dark chocolate flakes, butterscotch pieces or coconut are fed into the ice cream making process by Vibra Screw’s AccuFeed screw feeder, at many well know ice cream makers. They chose the AccuFeed because of it’s ability to accurately meter many different types of ingredients and it is very easy to clean when product changes are made.

Ever wonder how they get those wonderful little pieces of goodies inside of ice cream. You know those chunks of toffee, dark chocolate flakes, butterscotch pieces or coconut are fed into the ice cream making process by Vibra Screw’s AccuFeed screw feeder, at many well know ice cream makers. They chose the AccuFeed because of it’s ability to accurately meter many different types of ingredients and it is very easy to clean when product changes are made.

Alexco Environmental offered an onsite solution including a 75-ton silo and feed system to feed hydrated lime to treat 200 to 800 gallons per minute of influent. Alexco contacted Vibra Screw Inc. of Totowa, New Jersey, for expertise on equipment for handling bulk powders to see what was needed and what could be shipped within a week. The company offered a volumetric screw feeder with variable speed drive and a controller with 4-20 mA remote speed input, which would allow the lime feed to automatically adjust to the changing pH of the influent. The higher the acidity, the more lime was continuously fed. The system would also treat the heavy metals

Alexco Environmental offered an onsite solution including a 75-ton silo and feed system to feed hydrated lime to treat 200 to 800 gallons per minute of influent. Alexco contacted Vibra Screw Inc. of Totowa, New Jersey, for expertise on equipment for handling bulk powders to see what was needed and what could be shipped within a week. The company offered a volumetric screw feeder with variable speed drive and a controller with 4-20 mA remote speed input, which would allow the lime feed to automatically adjust to the changing pH of the influent. The higher the acidity, the more lime was continuously fed. The system would also treat the heavy metals