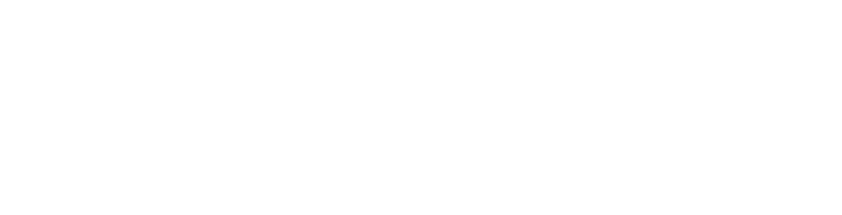

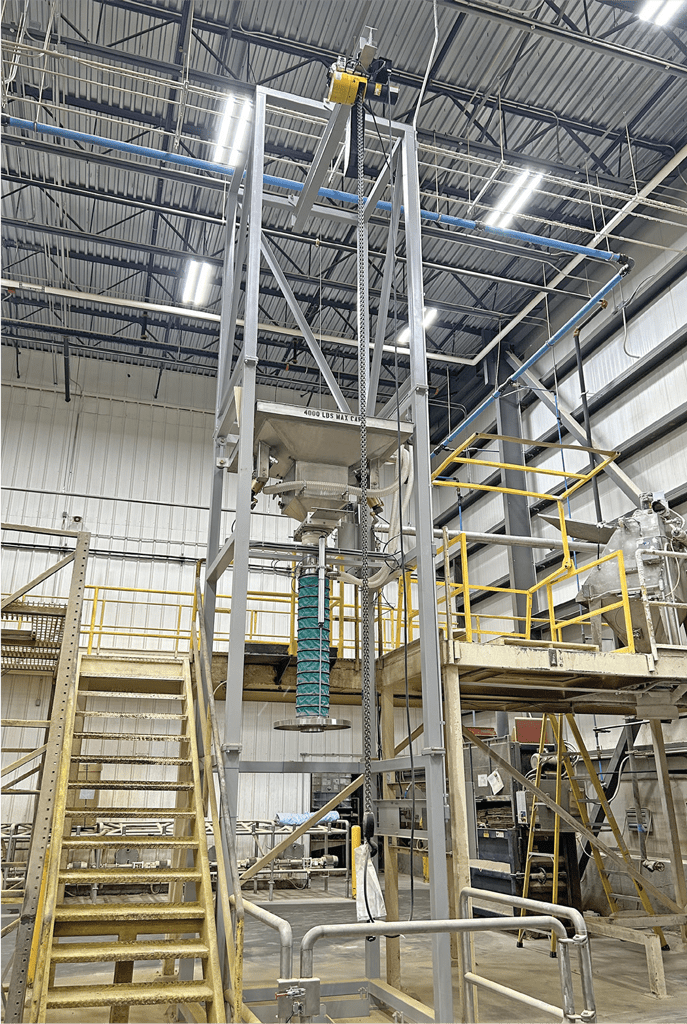

TOTOWA, NJ — Vibra Screw, Inc., a leader in solids processing and solids handling solutions, has expanded and its line of Bin Activators, with a new vibrator assembly, sanitary design, and variable rates leading the featured improvements. Smaller units 6 ft. and under now come standard with a vibrator that is more economical while offering simplified vibration adjustment. New sanitary features include an open design without cross members for complete and unhindered self-cleaning of material. In addition, a new special baffle arrangement allows rate adjustment without the need for a separate feeder.Vibra Screw’s line of Bin Activators now also includes an OEM line of Bin Dischargers that provide a simplified and more economical alternative to standard dished head bin activators for most bulk material applications.As with all Vibra Screw equipment, the Bin Activators and Bin Dischargers are unconditionally guaranteed to perform in the service for which they are sold. With a staff of experienced and talented engineers, technicians and crafts people, Vibra Screw manufactures high quality equipment to store, discharge, meter, convey, size and blend solid materials. The company’s comprehensive product range includes bulk bag unloaders and fillers, volumetric feeders, bin activators, vibrating feeder/conveyors, loss-in-weight feeders, storage pile activators, live bottom bins, live bins, continuous blenders, screeners, controls, and turnkey systems.