TOTOWA, NJ — Vibra Screw, Inc., a leader in solids processing and solids handling solutions, has been awarded a mid-six-figure contract with the People’s Republic of China to supply Bin Activators and Heavy Duty Feeders for a coal conversion plant in Inner Mongolia, it was announced by Gene Wahl, Vibra Screw President.The owner of the plant is Shenhua Coal, Co., Beijing; it was designed by Axens International, Princeton, NJ, and plant procurement was handled by Sinopec Engineering, Beijing. The actual purchase of the Vibra Screw equipment was handled by Govoni Sim Bianca Impianti, SpA, Italy, who are supplying most of the equipment for the plant.The coal plant is the first of a planned total of five facilities that will help to meet the rapidly increasing demand for energy concurrent with the 14% growth rate in the Chinese economy.According to Mr. Wahl, the equipment will be used to take coal out of silos and transport it so that it can be mixed with a catalyst in order to produce a more thermally efficient material that will be used to generate electricity.“The process involves pre-wetting pulverized coal with a catalyst before it is mixed with more liquid catalyst in large mix tanks,” he explained. “The coal, which has a high bulk density, bridges in storage and will not flow unaided. Once flow has been accomplished, the coal must then be accurately metered and weighed against the end products to ensure efficiency of the process. Since pulverized coal is very difficult to meter, the accuracy of the feed system is critical to the entire operation, which will run at literally thousands of tons a day.”Controlled vibration in the Vibra Screw Bin Activators will keep the coal moving without interruption from the storage silos into Vibra Screw Heavy Duty Feeders which will deliver the coal accurately into impact weighers. Accuracy of the Heavv Duty Feeders will also be achieved by controlled vibration, which densifies material, assures uniform filling

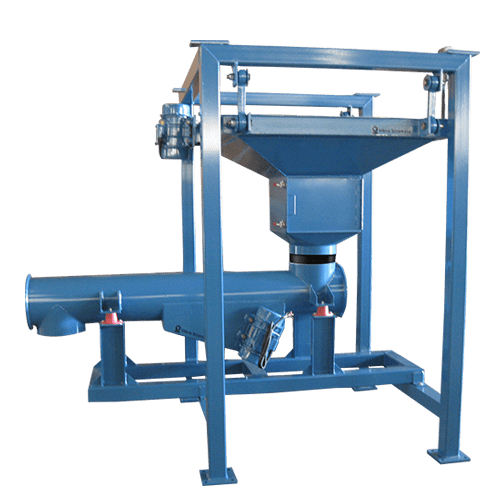

HD Screw Feeder

Vibra Screw, Inc., a leading manufacturer of equipment and systems for precision processing of dry bulk materials, has introduced a completely packaged system that simplifies the wetting and metering of activated carbon in water treatment systems. Vibra Screw’s continuous duty system includes a bulk bag unloader, volumetric screw feeder, educter and cone wetting unit for use when a sorbent is required to absorb pollutants. The lack of mixers, pumps, and tanks used in the system virtually eliminates maintenance and makes delivery and handling of activated carbon or other sorbents easy. The activated carbon system accepts bulk bags as large as 4,000 lbs., feeds hard-to-handle powders with accuracy as high as + 0.5 / 2% and replaces batch methods currently used to treat water. Vibra Screw also provides all liquid metering components, low water alarms, shut-offs, material level indicators, cycle timers, programmable electronic controls for monitoring and inventory control and wiring, required to operate the volumetric screw feeder as part of the package. Capacities range as low as 1 lb./hr. and only water hook-up and 110 V AC power are required to operate the system. Vibra Screw introduced the concept of controlled vibration to condition and drive bulk materials into and through a process more than 40 years ago. Today they manufacture the broadest line of equipment incorporating this feature including bin activators, bulk bag unloaders, volumetric screw and belt feeders, and all types of graimetric feeds, blenders, and controls.