New Vibra Screw LBB Volumetric Feeder Combines Accuracy with Economic Simplicity combines the accuracy of a weigh feeder with the economic simplicity of a volumetric device. The LBB Volumetric Feeder’s unique design features the positive hoppering of an on-board Vibra Screw bin activator with a patented nozzle that uniformly delivers material to the feeder’s belt. Since the Feeder’s design is simple as compared to complex weigh feeders, initial start-up and maintenance costs are significantly reduced. The LBB Volumetric Feeder delivers accuracies of 1-2% over feed ranges up to 100 to 1, and handles nearly any bulk material. With no internal parts, the unit feeds without material degradation, offering a distinct advantage with abrasive, waxy and pressure sensitive materials including chemicals, soaps, pigments, and food stuffs. As with all Vibra Screw equipment, the type LBB Volumetric Feeder is unconditionally guaranteed to perform in the service for which they are sold. With a staff of experienced and talented engineers, technicians and crafts people, Vibra Screw manufactures high quality equipment to store, discharge, meter, convey, size and blend solid materials. The company’s comprehensive product range includes bulk bag unloaders and fillers, volumetric feeders, bin activators, vibrating feeder/conveyors, loss-in-weight feeders, storage pile activators, live bottom bins, live bins, continuous blenders, screeners, controls, and turnkey systems.

News/Events

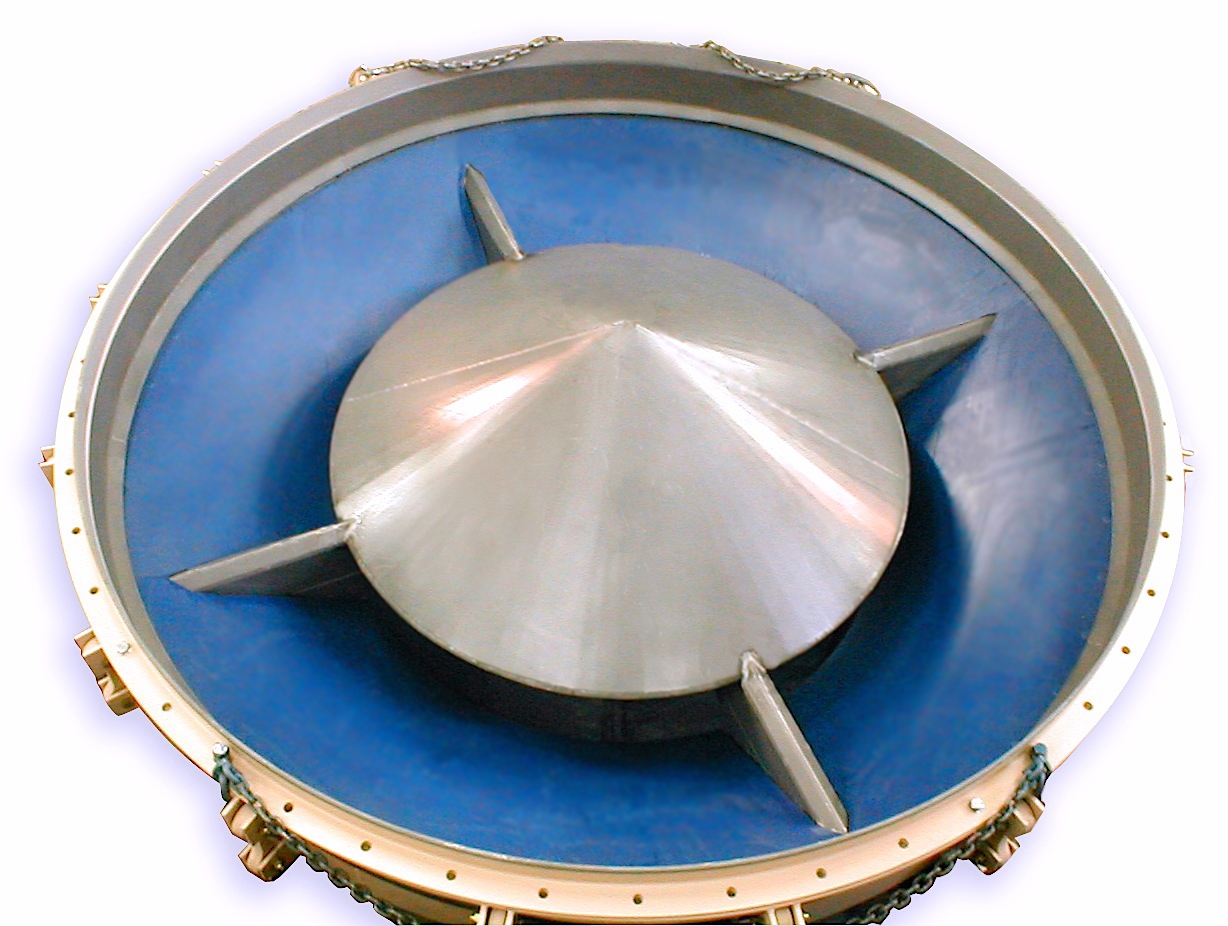

TOTOWA, NJ — Vibra Screw, Inc., a leader in solids processing and solids handling solutions, has expanded and its line of Bin Activators, with a new vibrator assembly, sanitary design, and variable rates leading the featured improvements. Smaller units 6 ft. and under now come standard with a vibrator that is more economical while offering simplified vibration adjustment. New sanitary features include an open design without cross members for complete and unhindered self-cleaning of material. In addition, a new special baffle arrangement allows rate adjustment without the need for a separate feeder.Vibra Screw’s line of Bin Activators now also includes an OEM line of Bin Dischargers that provide a simplified and more economical alternative to standard dished head bin activators for most bulk material applications.As with all Vibra Screw equipment, the Bin Activators and Bin Dischargers are unconditionally guaranteed to perform in the service for which they are sold. With a staff of experienced and talented engineers, technicians and crafts people, Vibra Screw manufactures high quality equipment to store, discharge, meter, convey, size and blend solid materials. The company’s comprehensive product range includes bulk bag unloaders and fillers, volumetric feeders, bin activators, vibrating feeder/conveyors, loss-in-weight feeders, storage pile activators, live bottom bins, live bins, continuous blenders, screeners, controls, and turnkey systems.

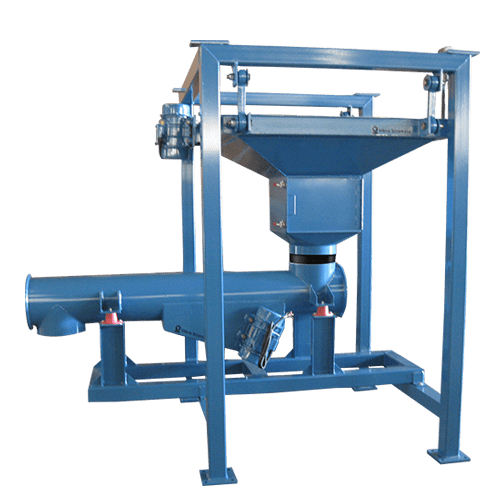

TOTOWA, NJ — Vibra Screw, Inc., a leader in solids processing and solids handling solutions, offers Bulk Bag Unloaders designed to provide a safe, dust-free and convenient way to handle and discharge bags. With an optional batch weigh design, the Bulk Bag Unloaders feature rugged load cells and easy-to-use electronics that allow the operator to control inventory, monitor bag contents, and accurately batch weigh preset quantities of material.With a wide variety of feed devices and weight control options, Vibra Screw Bulk Bag Unloaders also offer such unique features as a bag support hopper for safe seating and sealing of the bag, standard two-point dust collection, no-spill collection hopper, and a vibration discharge system for difficult to handle materials. Complete systems with integrated feeders feeders and conveyors are also available to control rate and elevate material to a process. As with all Vibra Screw equipment, the Bulk Bag Unloaders are unconditionally guaranteed to perform in the service for which they are sold. With a staff of experienced and talented engineers, technicians and crafts people, Vibra Screw manufactures high quality equipment to store, discharge, meter, convey, size and blend solid materials. The company’s comprehensive product range includes bulk bag unloaders and fillers, volumetric feeders, bin activators, vibrating feeder/conveyors, loss-in-weight feeders, storage pile activators, live bottom bins, live bins, continuous blenders, screeners, controls, and turnkey systems.

TOTOWA, NJ — Vibra Screw, Inc., a leader in solids processing and solids handling solutions, offers AccuFeed Loss-in-Weight Feeders that provide accuracies to ± 1/4% in gravimetric mode, where the weight signal is far more stable than in other systems.Designed to maximize accuracy through controlled vibration during the refill cycle, the Vibra Screw AccuFeed plastic-bodied Loss-in-Weight Feeder is available in screw diameters from 1” – 6” and capacities from 2.8 to over 600 cu.ft./hour. The units are constructed of food grade polyethylene which is inert and non-corrosive. The Feeder offers versatility in hopper selection, adapts easily to a wide variety of storage/discharge systems, and affords easy cleaning between material changes.AccuFeed is also available off-the-shelf at a price significantly lower than comparable steel loss-in-weight feeders, and is easily adapted to a broad range of applications by the simple addition of a secondary trough conditioning screw for non free-flowing materials. User-friendly, microprocessor-based controls feature a membrane keyboard and easy-to-read display that distinguishes actual weight from plant electronic noise. As with all Vibra Screw equipment, the AccuFeed Loss-in-Weight Feeders are unconditionally guaranteed to perform in the service for which they are sold. With a staff of experienced and talented engineers, technicians and crafts people, Vibra Screw manufactures high quality equipment to store, discharge, meter, convey, size and blend solid materials. The company’s comprehensive product range includes bulk bag unloaders and fillers, volumetric feeders, bin activators, vibrating feeder/conveyors, loss-in-weight feeders, storage pile activators, live bottom bins, live bins, continuous blenders, screeners, controls, and turnkey systems.

TOTOWA, NJ — Vibra Screw, Inc., a leader in solids processing and solids handling solutions, has announced the availability of a new case history that describes how a major Eastern toll processor was able to simplify its new plant design and considerably save on costs by choosing a simpler volumetric approach to bulk materials handling rather than a more complicated gravimetric loss-in-weight solution.In this particular installation, the processor incorporated bulk bag unloaders, bin activators, screw and belt feeders, blenders, tube conveyors, bucket elevators, bag fillers, storage silos and live bottom bins into a highly efficient system for feeding and metering mineral blends into two identical packaging lines. Customized PLC controls were also provided by Vibra Screw to synchronize the diverse filling, blending, and discharge functions required to meet application requirements.All of the Vibra Screw equipment was unconditionally guaranteed to perform in the service for which it was sold. With a staff of experienced and talented engineers, technicians and crafts people, Vibra Screw manufactures high quality equipment to store, discharge, meter, convey, size and blend solid materials. The company’s comprehensive product range includes bulk bag unloaders and fillers, volumetric feeders, bin activators, vibrating feeder/conveyors, loss-in-weight feeders, storage pile activators, live bottom bins, live bins, continuous blenders, screeners, controls, and turnkey systems.

TOTOWA, NJ — Vibra Screw, Inc., a leader in solids processing and solids handling solutions, offers Vibrating Feeder/Conveyors that simply and economically feed powders, flakes, or agglomorates without dust and degradation. The Vibra Screw pan and tube conveyors feature two highly efficient externally mounted vibrators that provide a unidirectional vibratory motion along the conveyor axis in constant or variable operation.With no screws, drag chains, bearing seals or other internal moving parts, the units require little or no maintenance and are ideal for sanitary applications. Individual units are available in lengths up to 25 feet, can be connected in series up to 100 feet, and offer capacities in both open pan or closed tube arrangements up to 36,000 cu. ft./hour. A variety of troughs, screws, and control options are available with designs for screening, dewatering, and elevating. As with all Vibra Screw equipment, the Vibrating Feeder/Conveyors are unconditionally guaranteed to perform in the service for which they are sold. With a staff of experienced and talented engineers, technicians and crafts people, Vibra Screw manufactures high quality equipment to store, discharge, meter, convey, size and blend solid materials. The company’s comprehensive product range includes bulk bag unloaders and fillers, volumetric feeders, bin activators, vibrating feeder/conveyors, loss-in-weight feeders, storage pile activators, live bottom bins, live bins, continuous blenders, screeners, controls, and turnkey systems.

Vibra Screw, Inc., a leading manufacturer of equipment and systems for precision processing of dry bulk materials, is offering a new Case History No. C-269 describing how a major snack food manufacturer uses Loss-in-Weight Feeders to control line dispersion in production of corn-based products.The manufacturer had been adding a small but precise amount of lime to the kettle feed stream by hand to soften and remove skins from corn kernels prior to processing and cooking. Since lime tends to settle and not stay suspended, the manual operation resulted in lumping and balling in the kettle along with wide accuracy fluctuations in a process that requires extremely critical ratios of lime to corn.Vibra Screw’s feed system incorporates a loss-in-weight screw feeder with a vibrated hopper, horizontal flexible screw auger and PLC controls for loss-in-weight operation. The system intermittently feeds 50 lbs. of lime to approximately 300 lbs. of corn per batch usually twice per hour for approximately four minutes per batch – a small but evenly distributed amount of lime. With each corn kernel evenly coated in the feed stream, lumping and lime settling have been completely eliminated.Vibra Screw introduced the concept of controlled vibration to condition and drive bulk materials into and through a process more than 40 years ago. Today they manufacture the broadest line of equipment incorporating this feature including bin activators, bulk bag unloaders, volumetric screw and belt feeders, and all types of graimetric feeds, blenders, and controls.

Vibra Screw, Inc., a leading manufacturer of equipment and systems for precision processing of dry bulk materials, has announced expansion of screw and hopper sizes in their highly successful line of Mini Feeders for dry material feeding.The new size ranges (screws are now available up to 1” maximum and hoppers up to 1 cu. ft.) are designed to accommodate materials that require more retention and conditioning time to ensure proper control and accuracy. The larger sizes also allow higher feed rates of up to 8.8 cu. ft. per hour with substantially reduced equipment weight – important in loss-in-weight applications where reduced weight allows use of smaller, more accurate scale components for precise continuous and batch feeding.Vibra Screw’s Mini Feeder line also features a modular design that allows the user to select the most economical design to meet specific material feed rates while retaining the flexibility to upgrade the feeder at any time to adapt to a change in materials or material characteristics.Vibra Screw introduced the concept of controlled vibration to condition and drive bulk materials into and through a process more than 40 years ago. Today they manufacture the broadest line of equipment incorporating this feature including bin activators, bulk bag unloaders, volumetric screw and belt feeders, and all types of graimetric feeds, blenders, and controls.

Vibra Screw, Inc., a leading manufacturer of equipment and systems for precision processing of dry bulk materials, has introduced a completely packaged system that simplifies the wetting and metering of activated carbon in water treatment systems. Vibra Screw’s continuous duty system includes a bulk bag unloader, volumetric screw feeder, educter and cone wetting unit for use when a sorbent is required to absorb pollutants. The lack of mixers, pumps, and tanks used in the system virtually eliminates maintenance and makes delivery and handling of activated carbon or other sorbents easy. The activated carbon system accepts bulk bags as large as 4,000 lbs., feeds hard-to-handle powders with accuracy as high as + 0.5 / 2% and replaces batch methods currently used to treat water. Vibra Screw also provides all liquid metering components, low water alarms, shut-offs, material level indicators, cycle timers, programmable electronic controls for monitoring and inventory control and wiring, required to operate the volumetric screw feeder as part of the package. Capacities range as low as 1 lb./hr. and only water hook-up and 110 V AC power are required to operate the system. Vibra Screw introduced the concept of controlled vibration to condition and drive bulk materials into and through a process more than 40 years ago. Today they manufacture the broadest line of equipment incorporating this feature including bin activators, bulk bag unloaders, volumetric screw and belt feeders, and all types of graimetric feeds, blenders, and controls.

Vibra Screw, Inc., a leading manufacturer of equipment and systems for precision processing of dry bulk materials, is offering a new bulk bag closing device designed to quickly, safely stop flow from partially discharged bulk bags.The lightweight, pneumatically-operated device uses dual blades vs. pinching devices to more effectively seal the bag opening at the center so the operator can tie it off for removal. Unlike slide gates which push bags off to one side and heavier, more expensive knife gates, butterfly valves or cruder rope closures, the pneumatic device provides a far simpler, safe and dust-free means to seal bags.The sealing device’s quick sealing capability is particularly effective where fluidized dry materials such as calcite, alumina or bentonite are handled, or materials that do not normally have fluid characteristics become fluid after aeration or during discharge from storage. The device is also highly effective in preventing plant humidity from reaching hygroscopic materials during discharge, during the closing procedure or during idle time in the process cycle.Vibra Screw introduced the concept of controlled vibration to condition and drive bulk materials into and through a process more than 40 years ago. Today they manufacture the broadest line of equipment incorporating this feature including bin activators, bulk bag unloaders, volumetric screw and belt feeders, and all types of graimetric feeds, blenders, and controls.