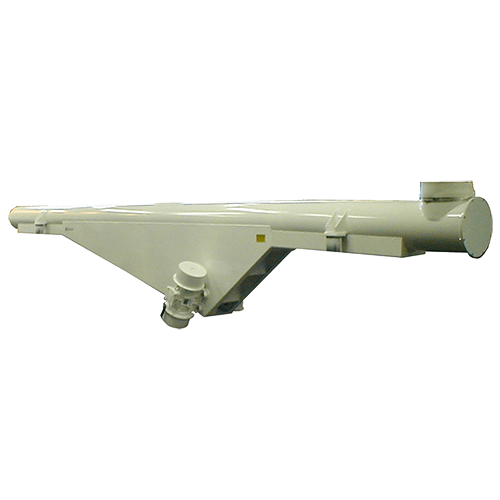

Vibra Screw, Inc., a leading manufacturer of equipment and systems for precision processing of dry bulk materials, offers a series of pan and tube conveyors designed to provide a simple and efficient means to meter and convey dry bulk materials.Designed to economically feed powders, flakes or agglomerates without dust or degradation, the pan and tube conveyors feature two highly efficient, externally mounted vibrators that provide a unidirectional vibratory motion along the conveyor axis in constant or variable operation. Flow rates are adjustable by resetting the eccentric force during operation or with an optional speed controller. With no screws, drag chains, bearing seals or other internal moving parts, the units require little or no maintenance and are ideal for sanitary applications.Individual units are available in lengths up to 25 feet, connectable in series up to 100 feet and offer capacities in both open pan or closed tube arrangements up to 36,000 cu/ft/hr. A variety of troughs, screws and control options are available along with designs for screening, dewatering or elevating.Vibra Screw introduced the concept of controlled vibration to condition and drive bulk materials into and through a process more than 40 years ago. Today they manufacture the broadest line of equipment incorporating this feature including bin activators, bulk bag unloaders, volumetric screw feeders and belt feeders and all types of gravimetric feeders, blenders and controls.