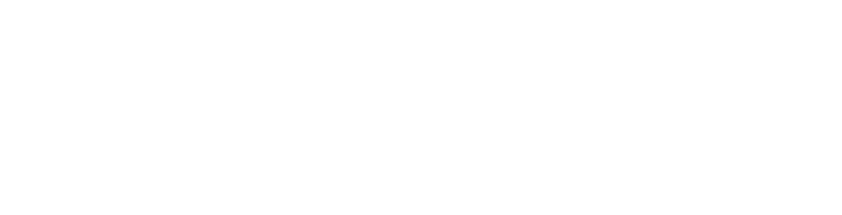

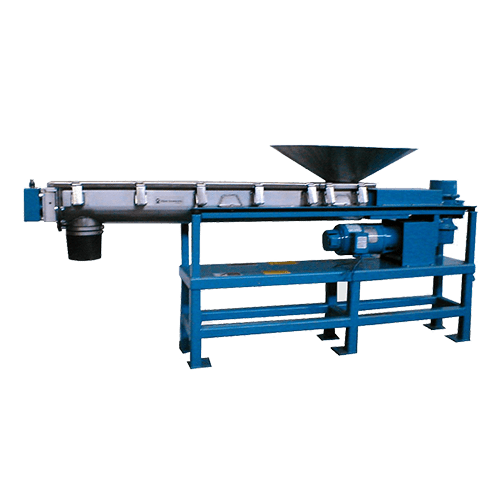

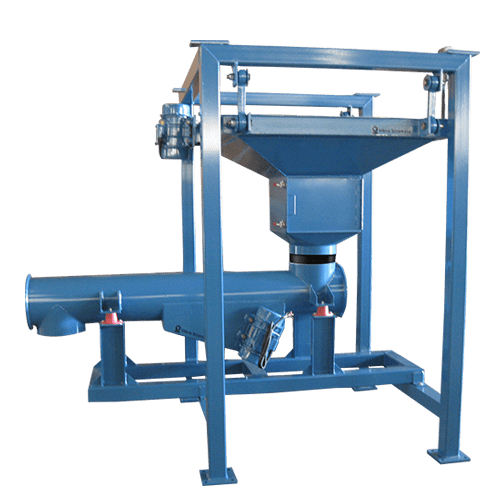

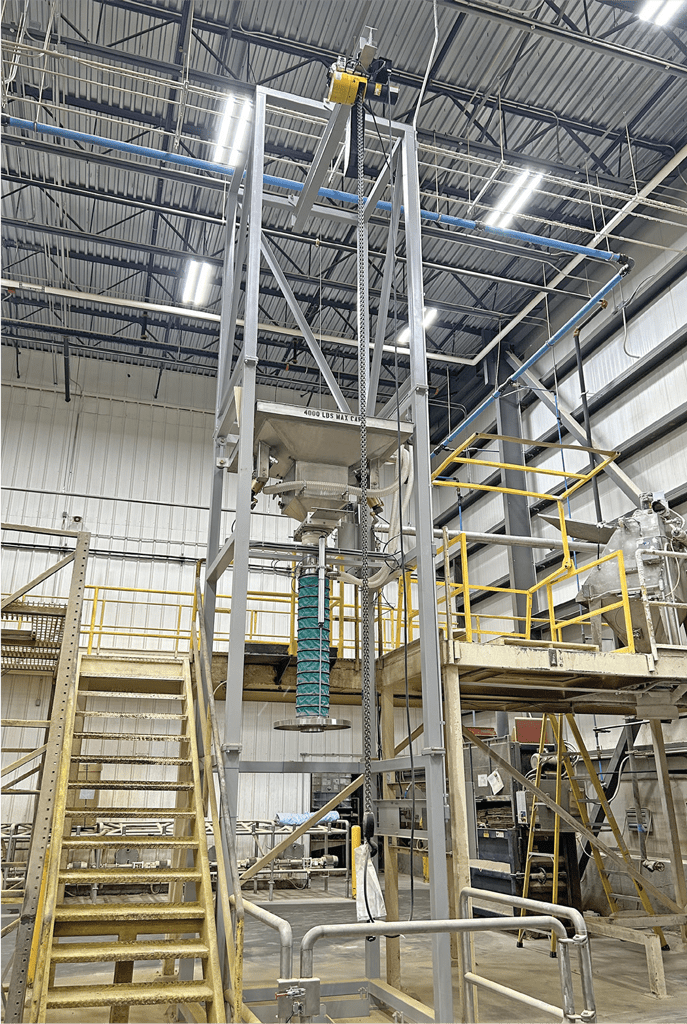

With a broad product line that addresses everything from main silo discharge to micro-ingredient feeding, Vibra Screw offers a continuous or batching weighing solution for every dry bulk feeding problem.Accurate weighing of dry bulk solids requires reliable and consistent flow of material from storage into the feed mechanism itself. Vibra Screw’s unique use of controlled vibration promotes flow, uniformly densifies the material, and completely fills and empties each flight of the feed screw. As a result, all Vibra Screw weigh feeding systems start as highly accurate volumetric feeders, eliminating inaccuracy during the refill cycle.Vibra Screw offers weigh feeders in screw sizes from 1/4″ to 18″ along with a broad range of belt, pan and tube feeder based systems.