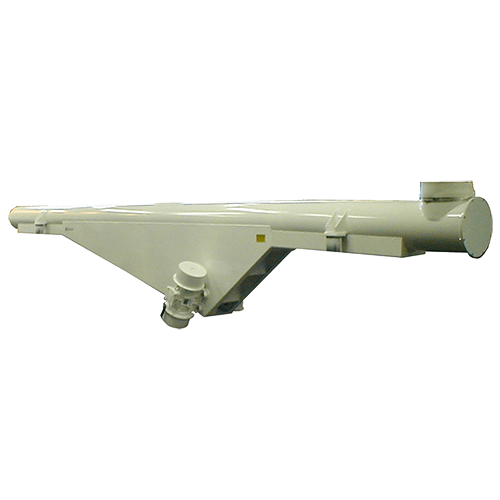

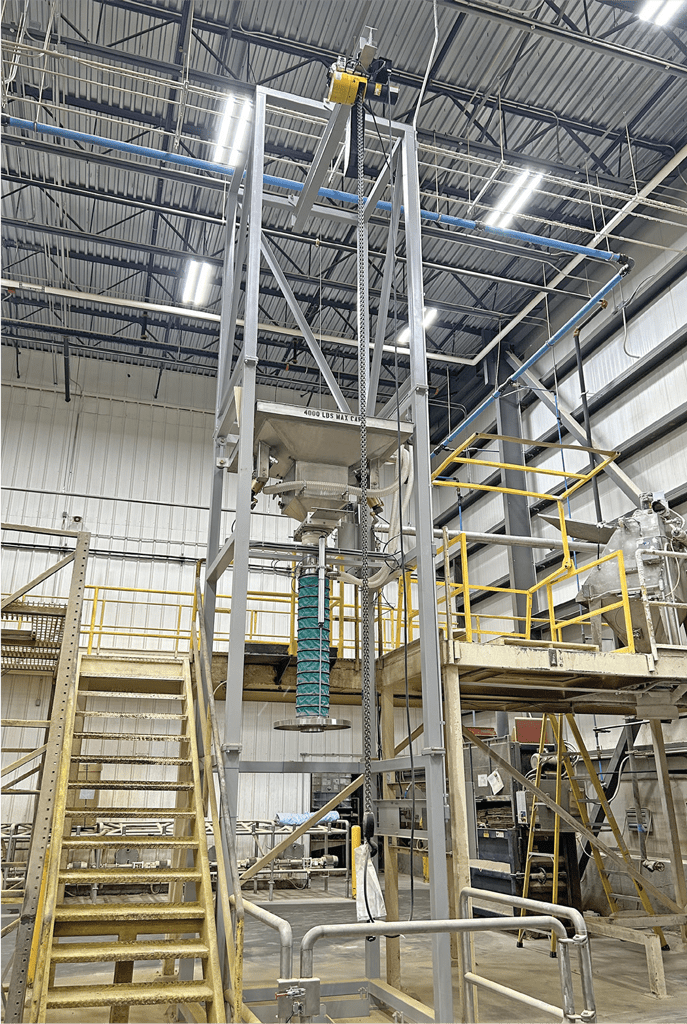

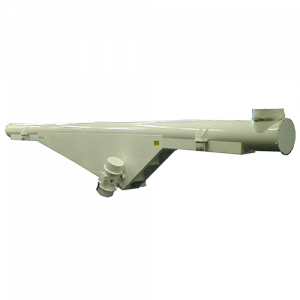

TOTOWA, NJ — Vibra Screw, Inc., a leader in solids processing and solids handling solutions, offers Vibrating Feeder/Conveyors that simply and economically feed powders, flakes, or agglomorates without dust and degradation. The Vibra Screw pan and tube conveyors feature two highly efficient externally mounted vibrators that provide a unidirectional vibratory motion along the conveyor axis in constant or variable operation.With no screws, drag chains, bearing seals or other internal moving parts, the units require little or no maintenance and are ideal for sanitary applications. Individual units are available in lengths up to 25 feet, can be connected in series up to 100 feet, and offer capacities in both open pan or closed tube arrangements up to 36,000 cu. ft./hour. A variety of troughs, screws, and control options are available with designs for screening, dewatering, and elevating. As with all Vibra Screw equipment, the Vibrating Feeder/Conveyors are unconditionally guaranteed to perform in the service for which they are sold. With a staff of experienced and talented engineers, technicians and crafts people, Vibra Screw manufactures high quality equipment to store, discharge, meter, convey, size and blend solid materials. The company’s comprehensive product range includes bulk bag unloaders and fillers, volumetric feeders, bin activators, vibrating feeder/conveyors, loss-in-weight feeders, storage pile activators, live bottom bins, live bins, continuous blenders, screeners, controls, and turnkey systems.

This complete line of vibrating tube conveyors moves virtually any bulk material without internal parts to wear or break. The machines are available in capacities up to 300 cu ft/hr, with single unit lengths up to 25 ft. They can be linked together for longer conveying distances and are available in carbon and stainless steel, with finishes to meet virtually any sanitary specification. Optional controls provide a 5:1 feed range and, when connected to a bin activator or bulk bag unloader, feed accuracies of 2-3% are possible for most materials. They also have the ability to handle fragile particles without degradation. A flexible connection at either end makes the machines entirely dust-tight.

This complete line of vibrating tube conveyors moves virtually any bulk material without internal parts to wear or break. The machines are available in capacities up to 300 cu ft/hr, with single unit lengths up to 25 ft. They can be linked together for longer conveying distances and are available in carbon and stainless steel, with finishes to meet virtually any sanitary specification. Optional controls provide a 5:1 feed range and, when connected to a bin activator or bulk bag unloader, feed accuracies of 2-3% are possible for most materials. They also have the ability to handle fragile particles without degradation. A flexible connection at either end makes the machines entirely dust-tight.